AI & IoT in Energy Management: The Future of Smart Factories

For decades, manufacturers have relied on manual energy audits and basic monitoring systems. The problem? These methods are:

- Reactive: Problems are only addressed after inefficiencies or failures occur.

- Time-Consuming: Energy audits take weeks to complete and analyze.

- Lacking in Real-Time Insights: No way to adjust power usage instantly based on real-time data.

Manufacturing plants today need AI-driven, real-time energy intelligence to optimize energy consumption proactively. This is where IoT-powered energy monitoring systems step in.

How AI & IoT Are Transforming Energy Management in Factories

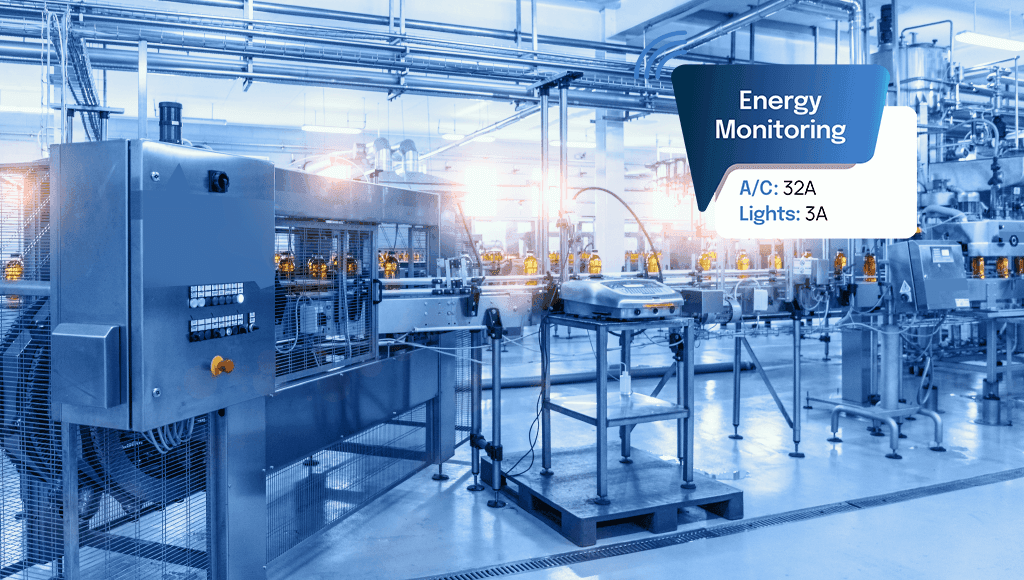

Real-Time Energy Monitoring with IoT Sensors

IoT-enabled smart factories use real-time sensors to monitor every machine’s energy consumption. These sensors continuously send data to a centralized platform, providing instant insights into power usage.

- Tracks energy consumption across different machines, departments, and shifts.

- Detects inefficiencies, such as idle machines still consuming power.

- Prevents power wastage by automating energy controls.

AI-Powered Predictive Analytics: Stopping Energy Waste Before It Happens

Traditional systems only report energy usage, but AI-powered platforms predict and optimize energy consumption based on real-time data.

- AI learns energy patterns from machines and suggests optimization strategies.

- Predicts energy anomalies that signal upcoming machine failures.

- Prevents costly power surges by adjusting energy loads dynamically.

Automated Energy Optimization & Cost Reduction

With AI and IoT, factories don’t just monitor energy—they automatically optimize it without human intervention.

- Intelligent load balancing: AI shifts power distribution to where it’s needed most.

- Peak demand control: Avoids excessive power usage during high-demand periods.

- Smart scheduling: Runs energy-intensive processes only when energy costs are lowest

Smart Energy Management for Sustainability & Compliance

Energy regulations are getting stricter. AI and IoT-based energy management systems help manufacturers:

- Reduce carbon footprints by tracking real-time emissions.

- Generate compliance reports automatically.

- Meet sustainability goals by ensuring optimal energy efficiency.

How ARD Solutions is Powering Smart Energy Management

At ARD Solutions, we are helping manufacturers take control of their energy usage with our ATAMAI Energy Platform—an AI & IoT-powered energy monitoring system designed for smart factories.

- Real-Time Monitoring – Track energy usage down to the individual machine level.

- AI-Driven Analytics – Predict and prevent energy waste before it happens.

- Seamless Integration – Works with your existing ERP and factory automation systems.

- Automated Energy Optimization – Reduce costs with AI-powered energy management.

Want to see how it works? Book a Free Demo Today!